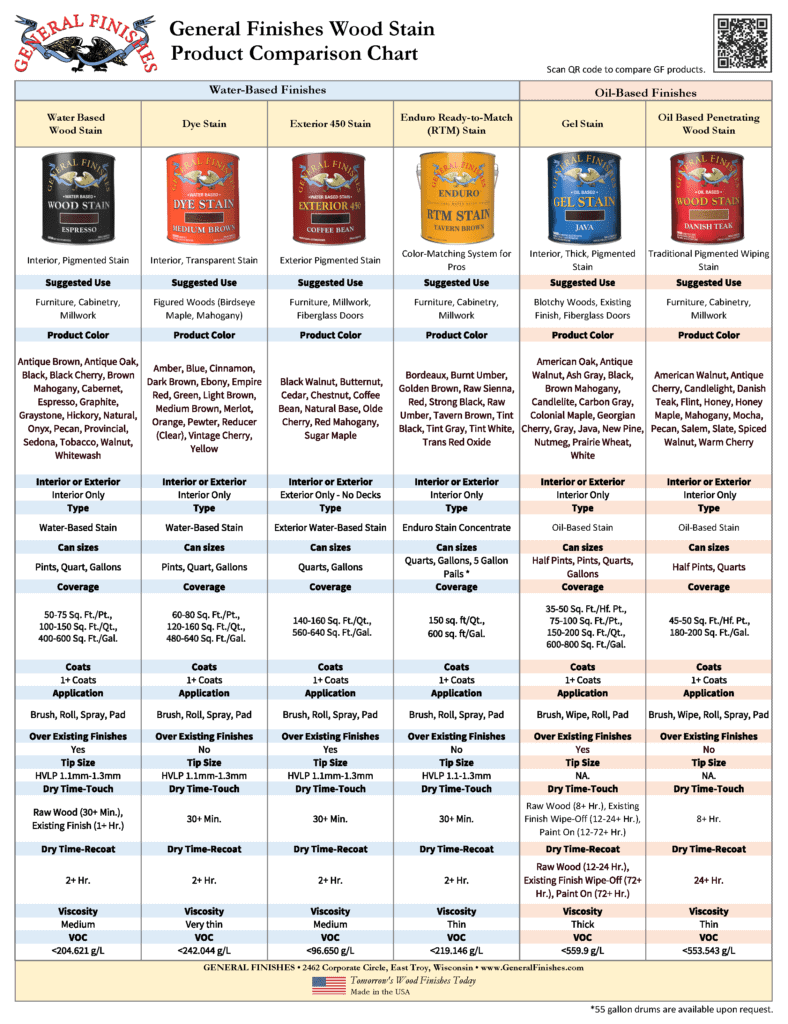

Gel Stain from General Finishes is home of the popular Java Gel Stain featured across the nation’s social media for upcycling furniture and cabinets. Gel wood stains are heavy-bodied and do not penetrate as deeply into the wood as liquid oil-based wipe-on stains do, providing the deepest, richest colors of any oil-based stain available.

All raw wood projects require preparation sanding before applying stain, and all existing finishes require prep cleaning and sanding. If you skip this critical step, your finish may fail.

Preparation for Raw Wood Projects

See our video: How to Prep Sand Raw Wood

Preparation for Projects with an Existing Finish

For high-use areas with heavy grime build-up and oil from hands, give your project a deeper cleaning.

See our video: How to Prepare Existing Finishes

Power Prep Cleaning Highly Used Existing Finishes

See our video: How to Power Prep Existing High Use Finishes for Stain or Paint

Alternative Cleaning Solutions for Existing Finishes (Not as aggressive or effective as denatured alcohol; requires rinsing.)

General Finishes Gel Stain Application Steps

7. Hand-Application over Raw Wood:

See our video on How To Apply Gel Stain to a Raw Wood Surface.

8. Optional: apply a second coat to deepen the color. Apply no more than 2 coats.

9. Finish with 3 coats of General Finishes topcoat, letting each coat dry 72 hours.

7. Dry Brushing Over an Existing Finish

8. Optional: apply a second coat to deepen the color. Apply no more than 2 coats.

9. Finish with 3 coats of General Finishes topcoat. See “Step 3: Topcoat Over Oil-Based Stain.”

7. Painting on Stain Without Wiping Away (raw wood or existing finish):

Always seal General Finishes oil-based stains with 3 coats topcoat to lock in the color. You can use either oil-based or water-based topcoat. When layering water-based and oil-based products, increase the dry time:

DO NOT use General Finishes Enduro-Var Topcoat with oil-based products.

General Finishes High Performance or General Finishes Flat Out Flat Water Based Topcoat

Mixing Gel Colors

Cleanup

Clean up application materials and hands with mineral spirits or waterless hand cleaner, like Goop or Gojo.

Disposal

Take great care when disposing of product-soaked applicators. Application materials, such as brushes and towels, containing oil-based products may spontaneously catch fire if improperly discarded. Immediately place all application materials soaked with this product in a sealed, water-filled metal container. Dispose of in accordance with local fire regulations.

Spills

Clean up spills with mineral spirits immediately while wet. If oil-based finishes dry, they are difficult to clean off any surface, clothes or carpet. Carpet may discolor if cleaned with mineral spirits.

Prevention

Protect your workspace with a tarp, your hands with gloves, and your clothes with an apron.

Life of Product

General Finishes products do not last forever, even when unopened. They are best used within 1 year. The life of the product may be extended several years with proper care and storage. Oil finishes tend to last longer than water finishes.

Storage Tips

See our video: Tips on Storing Leftover Finishes

Oil-based products start to harden and cure when exposed to oxygen. The following best practices will increase the life of your product:

STORING MIXTURES

Alternative Storage Containers

Gel Stain hardens faster than other products. It may soften slightly if a small amount of mineral spirits is added.

Gel Stain Warnings and Warranties

Limited Warranty

General Finishes products must be tested to your complete satisfaction before using. General Finishes will not be responsible for color satisfaction, misapplication, nor compatibility with other manufacturers’ products. General Finishes will be responsible only for the cost of our products, and not for costs such as labor, damage or project replacement.

Contamination and Compatibility

Our finishes are engineered as a system and are compatible with each other. General Finishes cannot guarantee an ideal refinish when applying our products on top of or combined with another company’s products or over surfaces that have been in contact with waxes, polishes or sprays containing contaminants such as silicone. Test for adherence and aesthetics before beginning.

FIRST AID: Seek immediate medical attention if symptoms occur due to the following. EYE CONTACT: Remove any contact lenses. Flush eyes with water for 20+ minutes while lifting upper & lower eyelids. SKIN CONTACT: Flush skin with water. Remove contaminated clothing & shoes & clean before reuse. INHALATION: Move to fresh air. Loosen tight clothing. If not breathing, if breathing is irregular, or if respiratory arrest occurs, trained personnel should provide artificial respiration or oxygen. INGESTION: Call physician immediately. Wash out mouth with water. Do not induce vomiting unless directed to do so by medical personnel. Never give anything by mouth to an unconscious person.

Prop 65 WARNING:

Warnings vary by color. See product label and SDS sheets for more information.

WARNING:

Warnings vary by color. See product label and SDS sheets for more information.

All stains need a top coat. Think of stain as the color and top coat as the sealer and protectant.

The high urethane content of General Finishes Gel Stains results in a lustrous finish that tends to fool people into assuming no sealant is required. The beauty of Gel Stain comes from thick thick urethane which can carry a LOT of color to any surface, but that color must be sealed in with top coat. An added bonus of top coat is that it also protects the wood from drying out.

Think of stain as the color and top coat as the sealer and protectant.

Gel Stain can be mixed with up to 50% Liquid Oil Stain but be aware that this will thin the viscosity. We recommend starting with 10% Liquid Oil Stain and testing to your satisfaction. Add more Liquid Stain as needed up to 50%. The mix will be thin and more translucent with less color saturation and intensity, but will not lose any of its properties for adhesion and curing.

How to thin Gel Stain to create a glaze:

We recommend adding up to 10% mineral spirits. You can add more mineral spirits, but test first. The mixture will thin out quickly and also reduces color intensity. Using more than 10% can affect the performance and durability of the finish, but as a glaze, this is not as critical an issue because your topcoat will protect the finish.

Yes, each layer will darken your project even more. You can also start with a lighter color Gel Stain and layer on darker colors.

It’s always possible to darken a stained surface, but you cannot lighten a stained surface after the finish has dried.

When the surface is still wet, you can try to lighten the color by scrubbing with mineral spirits. If the finish has hardened, you will need to sand down your current stain and start over or use one of our paints.

You can mix GF Gel Stain colors to create a custom color.

You can also thin Gel Stain with 10-15% mineral spirits.

Always test our color on a hidden area of your project before beginning.

Yes, you can mix similar products together at any ratio to make more color options.

You can also mix with 10% General Finishes Liquid Oil Based Wood Penetrating Stains to obtain a slightly thinner stain than the normal Gel Stain formula.

As the Gel Stain is used, the volume of stain in the can is displaced with air, causing the stain to start curing. Gel Stains harden up more quickly than liquid oil stains for all the reasons folks love them – the extra colorants and solids within the stain that provide such great coverage also harden up more quickly than other stains.

During storage, the oxygen or moisture that’s sealed in the container continues to cure and thicken your stored product, ruining the leftovers. Here are some tips to ensure your Gel Stain remains in great working condition.

Gel Stain is engineered for wood, but it has successfully adhered to more surfaces than we could have imagined. However, since tile cannot be abraded properly though sanding, lasting adhesion may be difficult if not impossible.

Milk Paint will have a better chance of adhering than Gel Stain. Dark Chocolate Milk Paint was created to match the color of Java Gel stain, for example. Both products are more likely to adhere if they are applied over a tile-appropriate primer.

Contact a tile store for recommendations regarding a primer that can help finishes stick to ceramic tile.

Even with primer, we cannot give any guarantees that the finish will adhere properly or last. Always test for compatibility between your primer and Milk Paint or Gel Stain before beginning.

If you choose to proceed, test your procedure on a hidden area first and let it cure for 7-10 days. Then further test the finish by duplicating normal wear and tear: washing, scrubbing, scratching, etc. to make sure the finish bonds to the surface.

Wax can be used over Gel Stain, if you prefer. Just let the Gel Stain dry 24-48 hours before applying the wax. Note: wax is not a durable product. It needs yearly reapplication, will show daily use (finger marks and smudges) and may be very difficult to remove if a future topcoat application is desired.

| Stain Sizes | 1/2 Pint, Pint, Quart |

|---|